Spring Steel Grades

Spring steel is a name given to a wide range of steels used in the manufacture of springs, prominently in automotive and industrial applications. These steels are generally low-alloy, medium-carbon steels or high-carbon steels with high yield strength and flexibility.

Common Grades of Spring Steel

- EN47: A silicon-manganese spring steel with excellent toughness and wear resistance.

- EN45: A silicon manganese spring steel often used in automotive suspension systems.

- 65Mn (Equivalent to EN47): High carbon steel with good hardness and elasticity.

- SUP9/SUP10: Japanese standards used for leaf and coil springs.

- SAE 5160: Chromium alloy steel commonly used in heavy-duty springs.

Applications

Spring steels are used in a variety of applications including:

- Automotive suspension springs

- Industrial machinery

- Knives and blades

- Lock picks

- Measuring tapes

The selection of a particular spring steel grade depends on the required strength, flexibility, and resistance to environmental factors such as corrosion and temperature.

EN42 Spring steel

EN42 is a high carbon spring steel known for its high yield strength and toughness. It is commonly used in manufacturing of springs, saws, blades, and other components requiring high elasticity and wear resistance.

Specification Standard

| Property | Details |

|---|

| Standard | BS 970-1955 EN42 |

| Material Type | High Carbon Spring Steel |

| Delivery Condition | Cold Rolled / Annealed / Hardened & Tempered |

| Thickness Range | 0.1 mm – 6 mm |

| Hardness (Annealed) | 180 – 220 HB |

| Hardness (Hardened) | 500 – 650 HV |

| Tensile Strength | 700 – 950 N/mm² (approx.) |

| Heat Treatment | Hardening: 780–820°C, Tempering: 150–200°C |

| Form | Sheets, Strips, Coils, or Custom Cut Sizes |

| Applications | Springs, Blades, Washers, Clutches, Light Machinery |

Properties

- High tensile strength and hardness

- Good wear resistance

- Can be hardened and tempered

- Suitable for cold forming

Applications

- Spring washers

- Clock springs

- Saws and blades

- Automobile components

EN45 Spring Steel

EN45 is a high carbon, silicon-manganese spring steel. It has excellent toughness, flexibility, and fatigue strength, making it ideal for high-stress components like automotive springs and cutting tools.

Specification Standard

| Property | Details |

|---|

| Standard | BS 970-1955 EN45 |

| Material Type | Silicon Manganese Spring Steel |

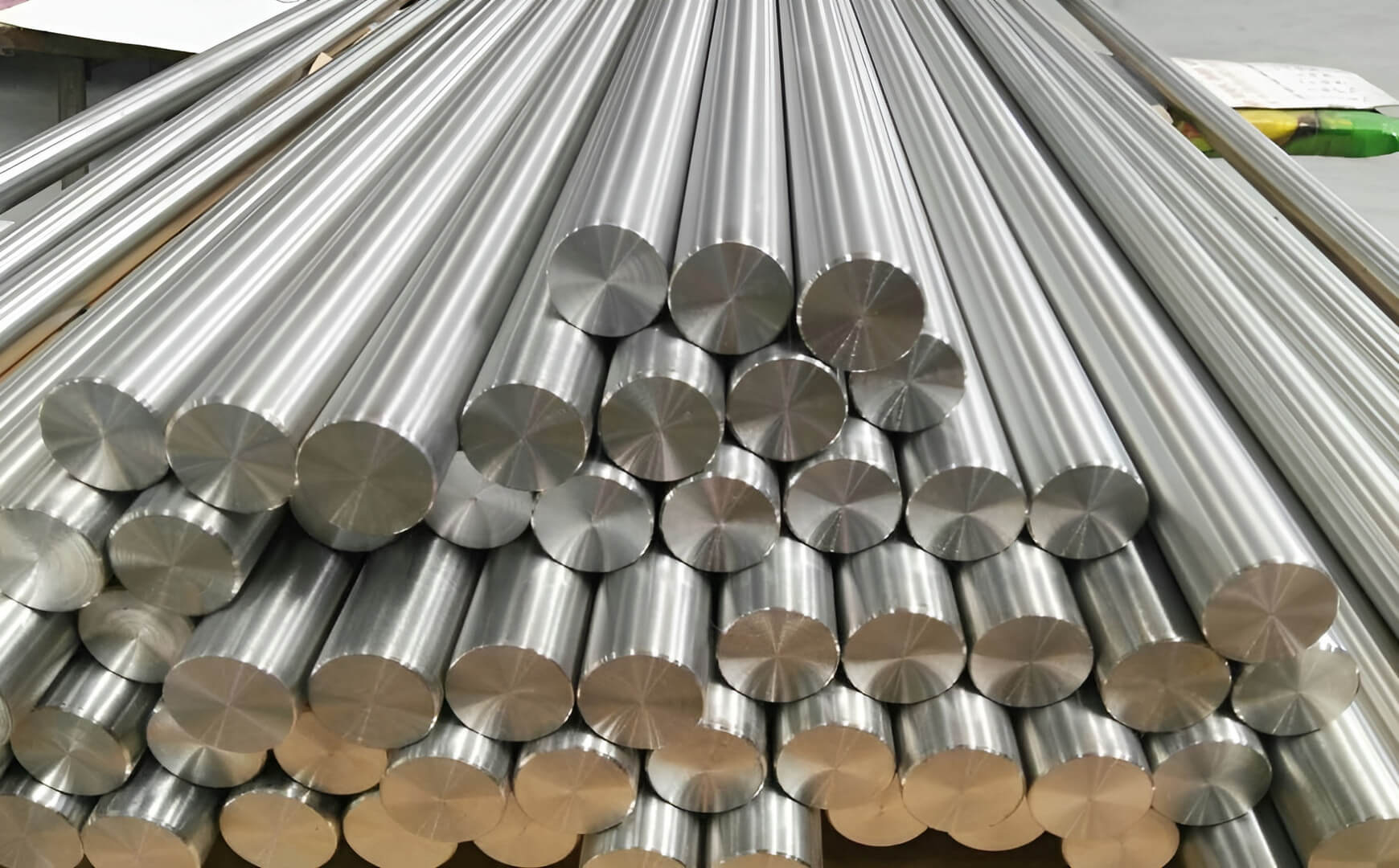

| Form | Round Bar, Flat Bar, Strip, Coil |

| Delivery Condition | Annealed, Hardened and Tempered |

| Hardness (Annealed) | 200 – 250 HB |

| Hardness (Hardened) | Up to 600 HV |

| Tensile Strength | 850 – 1100 N/mm² (after heat treatment) |

| Heat Treatment | Hardening at 830–860°C, Tempering at 400–600°C |

Chemical Composition

| Element | Percentage (%) |

|---|

| Carbon (C) | 0.50 – 0.60 |

| Manganese (Mn) | 0.70 – 1.00 |

| Silicon (Si) | 1.50 – 2.00 |

| Chromium (Cr) | Up to 0.25 |

| Phosphorus (P) | Max 0.05 |

| Sulphur (S) | Max 0.05 |

Properties

- High resilience and fatigue resistance

- Good toughness and ductility

- Excellent for high-load applications

- Good heat treatable for increased hardness

Applications

- Automotive leaf springs

- Heavy-duty coil springs

- Swords and long blades

- Railway components

- Shock-resistant tools

EN47 Spring Steel

EN47 is a high carbon chromium-vanadium spring steel known for its high fatigue strength, toughness, and ability to withstand heavy loads. It is commonly used for vehicle suspension springs, leaf springs, and heavy-duty components requiring resilience and hardness.

Specification Standard

| Property | Details |

|---|

| Standard | BS 970-1955 EN47 |

| Material Type | Silicon Chromium Vanadium Spring Steel |

| Form | Bars, Sheets, Strips, Coils |

| Delivery Condition | Hardened and Tempered / Annealed |

| Hardness (Annealed) | 200 – 250 HB |

| Hardness (Hardened) | Up to 600 HV |

| Tensile Strength | 900 – 1200 N/mm² (after heat treatment) |

| Heat Treatment | Hardening at 830–860°C, Tempering at 400–600°C |

Chemical Composition

| Element | Percentage (%) |

|---|

| Carbon (C) | 0.50 – 0.60 |

| Manganese (Mn) | 0.80 – 1.00 |

| Silicon (Si) | 0.10 – 0.35 |

| Chromium (Cr) | 0.90 – 1.20 |

| Vanadium (V) | 0.15 – 0.25 |

| Phosphorus (P) | Max 0.05 |

| Sulphur (S) | Max 0.05 |

Properties

- High fatigue and impact resistance

- Excellent wear and shock resistance

- Good toughness and hardenability

- Suitable for high-load and dynamic applications

Applications

- Automotive leaf and coil springs

- Heavy-duty suspension components

- Railway and agricultural machinery parts

- Tools requiring durability under stress

C60 Spring Steel

C60 is a high carbon steel grade with high strength, wear resistance, and moderate toughness. It is often used in applications that require hardening and tempering to achieve a strong and durable surface.

Specification Standard

| Property | Details |

|---|

| Standard | EN 10083-2 / DIN C60 / AISI 1060 |

| Material Type | High Carbon Steel |

| Form | Round Bar, Flat Bar, Sheet, Strip |

| Delivery Condition | Annealed / Hardened & Tempered |

| Hardness (Annealed) | 170 – 207 HB |

| Tensile Strength | 700 – 950 N/mm² (after heat treatment) |

| Heat Treatment | Hardening: 820–860°C, Tempering: 550–660°C |

Chemical Composition

| Element | Percentage (%) |

|---|

| Carbon (C) | 0.55 – 0.65 |

| Manganese (Mn) | 0.60 – 0.90 |

| Silicon (Si) | Max 0.40 |

| Phosphorus (P) | Max 0.04 |

| Sulphur (S) | Max 0.05 |

Properties

- High surface hardness after heat treatment

- Good wear resistance

- Medium machinability

- Low weldability

Applications

- Automobile components (e.g., gears, crankshafts)

- Hand tools and knives

- Spring clamps and discs

- Engineering and industrial parts requiring wear resistance

C70 Spring Steel

C70 is a high carbon steel grade commonly used for manufacturing of springs and components requiring high wear resistance and elasticity. After heat treatment, it achieves excellent hardness and tensile strength.

Specification Standard

| Property | Details |

|---|

| Standard | EN 10132-4 / DIN C70 / AISI 1070 |

| Material Type | High Carbon Spring Steel |

| Form | Strips, Sheets, Coils, Bars |

| Delivery Condition | Annealed / Hardened & Tempered |

| Hardness (Annealed) | 180 – 220 HB |

| Tensile Strength (Hardened) | 900 – 1100 N/mm² |

| Heat Treatment | Hardening at 780–820°C, Tempering at 180–220°C |

Chemical Composition

| Element | Percentage (%) |

|---|

| Carbon (C) | 0.65 – 0.75 |

| Manganese (Mn) | 0.60 – 0.90 |

| Silicon (Si) | Max 0.35 |

| Phosphorus (P) | Max 0.04 |

| Sulphur (S) | Max 0.05 |

Properties

- High tensile and yield strength

- Good wear and fatigue resistance

- Moderate ductility

- Capable of cold forming after annealing

Applications

- Spring washers

- Industrial springs and clips

- Blades and cutting tools

- Shock absorber components

- Automotive and agricultural machinery parts

C75 Spring Steel

C75 is a high carbon steel grade used for applications requiring high strength, hardness, and wear resistance. It offers good elasticity and fatigue resistance, making it ideal for high-performance spring applications.

Specification Standard

| Property | Details |

|---|

| Standard | EN 10132-4 / DIN C75 / AISI 1075 |

| Material Type | High Carbon Spring Steel |

| Form | Strips, Coils, Sheets, Bars |

| Delivery Condition | Annealed / Hardened & Tempered |

| Hardness (Annealed) | 190 – 230 HB |

| Tensile Strength (Hardened) | 1000 – 1200 N/mm² |

| Heat Treatment | Hardening: 790–830°C, Tempering: 180–220°C |

Chemical Composition

| Element | Percentage (%) |

|---|

| Carbon (C) | 0.70 – 0.80 |

| Manganese (Mn) | 0.50 – 0.80 |

| Silicon (Si) | Max 0.40 |

| Phosphorus (P) | Max 0.035 |

| Sulphur (S) | Max 0.035 |

Properties

- High hardness and strength

- Excellent wear and fatigue resistance

- Good elasticity

- Can be cold formed after annealing

Applications

- Spring blades and flat springs

- Measuring tapes and clock springs

- Saw blades

- Industrial clutches and brake bands

- Steel strapping and spring washers

C55 Spring Tool Grade

C55 Steel Composition

| Element |

Percentage |

| Carbon (C) |

0.52–0.60% |

| Manganese (Mn) |

0.60–0.90% |

| Silicon (Si) |

0.10–0.35% |

| Phosphorus (P) |

≤ 0.035% |

| Sulfur (S) |

≤ 0.035% |

C55 Steel Properties

| Property |

Value |

| Tensile Strength |

600–900 MPa |

| Yield Strength |

Approx. 350 MPa |

| Hardness |

180–250 HB |

Applications of C55 Steel in Springs

C55 steel is commonly used for manufacturing various types of springs, such as:

- Compression Springs

- Extension Springs

- Torsion Springs

- Wire Forms

Heat Treatment of C55 Steel

The steel can undergo heat treatment to improve its hardness and mechanical properties. The following processes are commonly used:

- Hardening: Heating to 830–880°C and then quenching in oil or water.

- Tempering: Tempering at temperatures around 450–650°C to adjust hardness and reduce brittleness.

C80 Spring Tool Grade

C80 Steel Composition

| Element |

Percentage |

| Carbon (C) |

0.75–0.85% |

| Manganese (Mn) |

0.60–0.90% |

| Silicon (Si) |

0.10–0.35% |

| Phosphorus (P) |

≤ 0.035% |

| Sulfur (S) |

≤ 0.035% |

C80 Steel Properties

| Property |

Value |

| Tensile Strength |

750–1050 MPa |

| Yield Strength |

Approx. 500 MPa |

| Hardness |

210–300 HB |

Applications of C80 Steel in Springs

C80 steel is commonly used for high-stress applications where a higher tensile strength and hardness are required. It is suitable for manufacturing:

- High-stress Compression Springs

- Extension Springs

- Torsion Springs

- Wire Forms

Heat Treatment of C80 Steel

The steel can undergo heat treatment to improve its hardness and mechanical properties. The following processes are commonly used:

- Hardening: Heating to 820–880°C and quenching in oil or water.

- Tempering: Tempering at temperatures around 450–650°C to reduce brittleness and adjust hardness.